High quality, made differently. We are making the highest quality eyewear, in an entirely different way; instead of a linear and extractive production process - which is used by most companies in the world - we are working hard to build our entire value chain under a circular, restorative and eventually regenerative model.

What do we mean by circular?

We mean moving away from the take –make– waste extractive way, and towards a model where we can design products “made to be made again”. This means that when the product reaches the end of its life, its materials are kept within the economy wherever possible. These can be productively used again and again, thereby creating further value and focusing on positive society-wide benefits.

What do we mean by restorative?

We will base our definition on what Pamela Mang and Bill Reed explain. A restorative design combines returning polluted or degraded sites back to a state of acceptable health through human intervention, with designs that reconnect people to nature.

What do we mean by regenerative?

We will quote Bill Reed’s approach once again. The regenerative design creates regenerative cultures, this means, cultures capable of learning, transforming and design as nature, responding and anticipating inevitable change.

A regenerative culture will emerge out of finding and living new ways of relating to self, community and to life as a whole. At the core of creating regenerative cultures is an invitation to live the questions together.

We aim for using our operations as a source of land conservation and the empowerment of local and rural entrepreneurs that can create a positive cycle of prosperity and sustainable development in their own communities.

At the same time, we want to inspire our community to reflect together on the question "What would the world look like if we understood that we are all nature?". We don't have an answer but the roads we are building while trying to answer this question are bringing us every day closer to nature.

Changing the way the production processes in hard goods works is not an easy task. We are committed to proving that it is possible to substantially change the way businesses operate, yet we are conscious that it is an ongoing process.

There is still much to improve, yet we are proud to see how much we have achieved so far. Collaboration, curiosity and the willingness to hear feedback to understand what we are doing wrong and join our heads with other people and organizations with whom we share values, to make it better, we believe is the core of any progressive, evolutionary path.

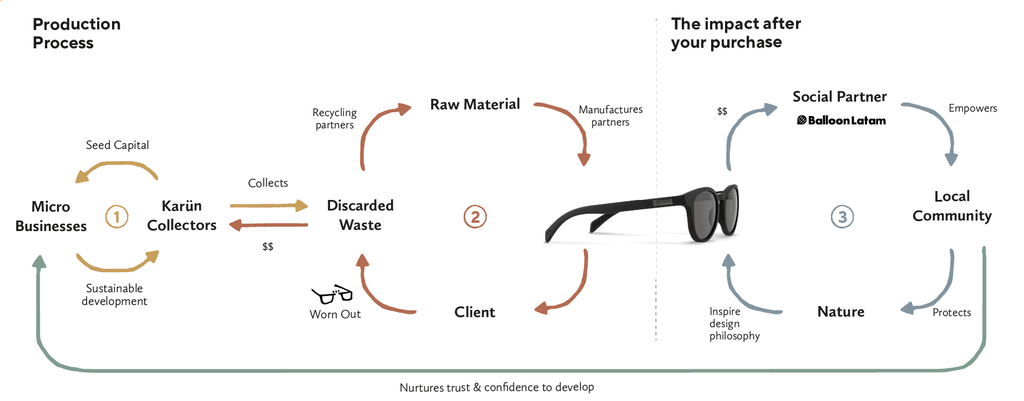

Explaining our value chain

We divided our value chain into two stages to explain better the flow of value through our model: First the Production Process itself and second, the Impact created from sales of our products.

1. Production Process

Karün collection process: First circle

It begins with the Karün collectors from the coast of Chile. They collect different types of materials, among which we find discarded plastic from the ocean and recycled metals, waste that affect our natural ecosystem (such as ropes, fishing nets, aluminum and copper), which we buy to use as raw material for the creation of most of our products.

By selling this raw material to us, the entrepreneurs are generating an additional source of income, which they use as seed capital to expand their own local microbusinesses.

This way the Karün recyclers don’t depend on waste to grow, they learn tools of how to manage their businesses, and then apply them to their own projects, to thrive and grow strong together with their families.

About the recycling and manufacturing stages: Entering the second circle

The discarded waste we receive from Karün collectors, we send it to our recycling partner Aquafil where the waste meets other discarded nylon to create the raw material. They are pioneers in a recycling system that ensures the quality of the raw material.

The ECONYL® regeneration system consists of 4 stages (Rescue-Regenerate-Remake-Reimagine):

- Rescue: The ECONYL® Regeneration System starts with rescuing waste. That waste is then sorted and cleaned to recover all of the nylon possible.

- Regenerate: Through a radical regeneration and purification process, the nylon waste is recycled right back to its original purity. That means ECONYL® regenerated nylon is exactly the same as virgin nylon.

- Remake: ECONYL® regenerated nylon is processed into pellets for the production of our sunglasses.

- Reimagine: The beauty of ECONYL® regenerated nylon is that it has the potential to be recycled infinitely, without ever losing its quality.

After this process, the waste is transformed into pellets which are sent to our manufacturing partners in Italy, China, South Korea and Turkey.

We would love to make our products in Chile, but the quality we want to meet to compete in the international market is not yet to be found in our country. That is why, in order to make efficient use of our resources, we are working hard to ensure the best quality, so our products can last a lifetime, and therefore avoid new waste. It is in this line that we decided to use stainless steel hinges and high quality glass, both of the best components you can find in the industry.

Conscious of the transportation consequences on the environment, we plan it as responsibly as we can. To minimize carbon footprint during transportation, raw materials are reduced in size and volume and shipping methods are responsibly selected, always prioritizing ships over planes.

We have a great relationship with the factories, they provide excellent working conditions for their employees and actively work with their own local communities in protecting their natural environment; in fact, one of the factories, the one in Italy, is located just outside a national park.

The product and packaging

After production, sunglasses are sent to our customers, making sure the material we use for packaging is as sustainable as it can be. Our booklet is made with recycled paper, our box is recycled cardboard, easy to recycle it again or to give it a new use. Our cases or bags for sunglasses are made from organic cotton or recycled leather, and the filling we use to send our packages is 100% corn-based. This means they are biodegradable and dissolve in water. They are also reusable and require less energy to produce them than other alternatives like styrofoam.

Closing the loop

If and when the sunglasses do meet the end of their life, we encourage our customers to send them back so we can avoid new plastic waste. In return, we give a discount for any new pair of Karün sunglasses. Old polycarbonate lenses can be recycled, and the frames can be regenerated thanks to Econyl ®, therefore with old sunglasses we can produce new ones, starting the circular chain once again.

2. The Impact after the sale

With the income we receive from sales of our sunglasses, we are funding an exciting 4-year programme developed by our social partner Balloon Latam in Cochamó and Puelo River Valley. People know it as “the Yosemite from Southamerica”. Cochamó’s population is 4.023 in a 3.908 square km territory. This area is characterized by a high demographic and productive dispersion, and great natural richness. It contains 99% of the native forests; it fosters more than 138 fauna species and they have found “huemules”, a type of deer from the Andes that is in danger of extinction. This is an area full of wildlife and pristine landscapes we feel the urgency to protect (click here for more details on how we are helping to protect Cochamó).

Through Balloon’s interventions, tools are delivered for the development of people and communities of the Cochamó and Puelo River Valleys, taking into account their local reality, cultural and geographical conditions and possibilities of productive development, while empowering and training change agents and social leaders.

In Karün we believe that a natural place with an empowered community and an economy that depends on the conservation of the environment is a place more likely to be conserved.

About our work to Reconnect

As we have explained, we try to be as coherent as we can be in everything that we do. At this point we are in a very demanding stage at Karün: growing large, with a small group of people. This is why we believe so strongly in the power of collaboration and in creating a process that aligns with our beliefs.

It is in this context that we created the Connection with nature plan for our team. This plan aims to bring our work and team closer to nature so we can truly set the base, slowly, to start living in harmony with nature. It has 3 elements: monthly classes with indigenous communities; weekly classes of meditation and learning about the principles of nature and how we can integrate them in our daily routines; quarterly adventures in nature to explore, learn about flora and fauna and connect with our source of life.

If you have questions or suggestions you can write directly to europe@karunworld.com or contact us HERE.